Asli Odman, an academic at Bilgi University, Istanbul, is part of the Tuzla Shipyard Region Monitoring Committee. The committee has just published a report on the working conditions and preventable series of accidents at the workplace.

As the third death on a shipyard in Tuzla this year was announced yesterday, she wrote an article about the current situation in the shipbuilding industry for bianet, summarised here.

Growth industry, more deaths

Odman points out that the shipbuilding industry has grown internationally; in Turkey, the industry has trebled in size in the last three years, but at the same time, the number of workers dying per year has risen from five to fifteen. As Odman says, “this is no coincidence.”

The estimated fourty shipyards in the Tuzla region on the outskirts of Istanbul and on the Marmara Sea coast have managed to increase the size of their enterprises by increasing work hours and the work rhythm.

In a report in April 2007, the Ministry of Employment and Social Security noted that of 44 shipyards only two had taken all precautions prescribed by the law in order to ensure work safety, while the others were delaying.

Killed by haste, not lack of hard hats

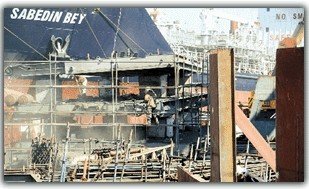

The workers in Tuzla are not dying because they are not wearing hard hats or goggles; in the shipbuilding sector, weights are measured not in tons but in gross tons – a piece of metal falling onto a worker weighs 3.5 tons. When these parts are lifted from one place to the next in a hurry in order to keep up with the “success” of the industry, forklifts are used instead of cranes in the narrow confines of the yard. If it falls, it kills the worker, technician or engineer.

Workers also die from falling off insecure scaffolding on the outside of ships, put up in a hurry.

They die because their employers, the shipyard owners with a great profit margin, are not ensuring work place safety.

There have been cases where workers have fallen into the sea or into the ship without anyone noticing for hours, even days. If, in the hurry to finish a contract, oxygen hoses and electrical cables are not kept apart, a welder can die in an explosion.

It is incomprehensible how such neglect on the part of the shipyard owners has been tolerated.

Countless subcontractors will never ensure basic safety

Another factor is the subcontracting system, which has been encouraged by owners in order to increase competitiveness and flexible employment.

With the subcontracting system, the main job of building a ship is divided into between 30 and 50 smaller projects, all carried out in the same yard; it is impossible for all the subcontractors to collaborate and provide workplace safety.

Again, the main employers, the shipyard owners, are avoiding their duties to ensure a safe yard.

Most workers not part of permanent staff

Another issue is insecure employment. Of around 1,000 workers per shipyard, only around 100 are registered as permanent staff, which means that there are only medical provisions and safety officers calculated for 100 people.

It is not surprising that the Limter-Is trade union for shipyard builders has to fight for “the right to live” before any other rights. This is the shadow side of the industry’s “success.”

The report by the monitoring commission has suggested that shipyard owners must take responsibility for all their workers, not only 10 percent of them, insure them and register them in their workplace. This also means that the Ministry of Employment needs to do its duty of inspection.

As new shipyards are opening in Turkey, it is vital that action be taken. (AO/TK)