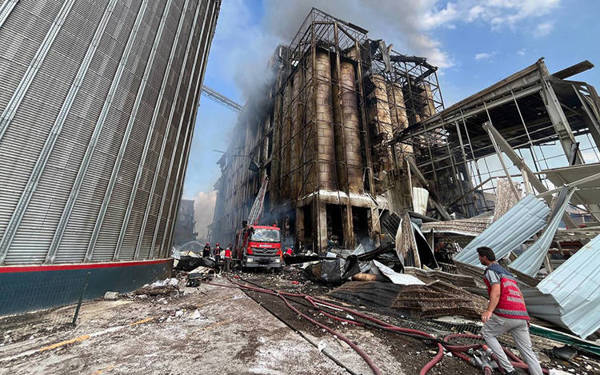

The expert report on the explosion at the Oba Makarna Factory in Hendek, Sakarya, on Sept 15, which killed five pople, has been released.

Prepared by three academic experts and an engineer, the report concluded that the explosion and fire occurred in the mill section of the factory, starting in the control room where electrical panels were located. The cause was identified as grain dust.

Deadly pasta factory explosion occurred despite recent inspection

The report stated, “It is concluded that a spark caused by a short circuit in the energy room ignited the flour dust present, leading to the explosion.” However, the primary cause of the explosion was identified as neglect of occupational safety measures. According to the report, risk analysis was not conducted properly, dust accumulation was overlooked, and issues were present in the electrical systems.

In the conclusion, the experts wrote: “The fire and explosion occurred due to regulatory non-compliance and a lack of preventive measures. It is believed that the incident could have been prevented if necessary precautions had been taken at the facility. The incident is attributed to the negligence of the employer and other responsible parties.”

Neglected Risks

The report highlighted the following safety violations:

- The existing risk analysis was inadequate for a facility of Oba Makarna’s scale and did not address all aspects of potential risks.

- A critical consideration for safety specialists analyzing risks in flour/pasta factories and mills is the danger of grain dust explosions. While dust explosions were mentioned in the risk analysis, they were not examined in depth.

- Heavy dust accumulation was observed in various parts of the mill section.

- Dust measurements were reportedly taken only in the area known as "Packaging," and the measurements were evaluated solely from a hygiene perspective. There was no evidence of dust levels in the mill section being monitored or tracked.

- The Explosion Protection Document (EPD) was prepared only to ensure the continuation of operations at the facility. It did not consider regulatory violations or potential hazards such as explosions, fires, or other dangers stemming from these violations.

- Electrical systems should be designed to be explosion-proof without additional attachments, repairs, tape, or wrappings. However, post-incident inspections revealed cables patched with electrical tape.

- Electrical panel covers were found open throughout the factory, including in the mill section, exposing them to dust and creating conditions conducive to dust accumulation.

- There was no evident culture of workplace safety. Workplace accidents were treated as routine or ordinary occurrences. Preventive and corrective measures following near-miss incidents or accidents were not effectively implemented. Recommendations and evaluations from safety specialists were not put into practice.

Company chair named responsible

The report identified Mehmet Musa Özgüçlü, Chairman of the Board of Oba Makarna, as primarily responsible for the explosion due to “violations of employer obligations.”

I.B., who prepared the Explosion Protection Document (EPD), was held primarily responsible for the explosion. The report stated that I.B. did not allocate sufficient time to inspect the facility while preparing the document, failed to adequately evaluate its scientific foundations, and overlooked the need for technological protective measures in areas with the highest risk of dust explosions, thereby preventing the recognition of potential hazards.

Occupational safety specialist D.T. was identified as secondarily responsible. According to the report, D.T. prepared the mandatory risk analysis, Explosion Protection Document, and periodic machine and equipment inspections without considering the dusty working environment. D.T. also failed to fulfill their responsibility to guide the implementation of more effective cleaning and maintenance practices and did not recommend halting operations to the employer or employer representatives, despite the risks posed by open panel covers, dusty conditions, and dust-accumulating electrical panels.

The report further stated that the mill manager, electrical manager, and administrative affairs manager were secondarily responsible for failing to fulfill their duties, which contributed to the explosion.